iPhone Motherboard Repair Tips

Video overzicht

-

-

A hot air gun is one of the most frequently used tools in phone repair, and the technical requirements for technicians are also very high. Both soldering and desoldering of motherboard components require a hot air gun.

-

Today, we will walk you through some basic steps to using a hot air gun for phone repair. First, let’s take a look at the types of hot air guns.

-

-

-

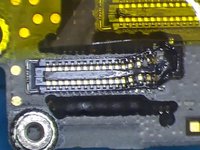

Hot air guns can be divided into the helical wind and vertical wind types. The helical wind type is mainly used to solder and desolder connectors, NAND, CPU, WiFi modules and other relatively large chips.

-

The vertical wind type is mainly used to solder and desolder small components like resistors and capacitors.

-

The helical wind type features gentle airflow and low heat, while the vertical wind type has concentrated airflow and high heat.

-

-

-

Gereedschap gebruikt in deze stap:Tweezers$4.99

-

Correct use of the hot air gun can enhance repair efficiency while incorrect use can damage the phone.

-

The temperature and airflow of the hot air gun must meet special requirements in different scenarios. The component can’t be removed or soldering will be defective if the temperature is set too low while components and PCB board will be damaged under high temperature.

-

What’s more, components will get blown away if the airflow is set too high. Therefore, proper use of the hot air gun is the key to phone repair Then we will show you how to use hot air gun properly for phone repair. First of all, let’s take a look at how to desolder small components.

-

Vertical wind hot air gun is used to desolder these kinds of components. The temperature should be set around 330 °C-365 °C and airflow around 1-3. Because the vertical wind hot air gun heats up so quickly, please wait to begin working until the temperature is stable after starting up.

-

In addition, the nozzle should be kept vertical from the component with a distance of 3-6 mm. You should heat evenly above the component for about 13-18 seconds. Then remove the component with tweezers.

-

-

-

For soldering, the soldering method is the same as the desoldering method. You need to put the component in position firstly and pay attention to the temperature as well as airflow.

-

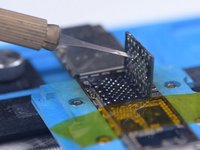

Next, let’s see how to desolder large chips with hot air gun. Corner adhesive needs to be removed when we use hot air gun to desolder large chips like NAND. Helical wind hot air gun is used to desolder these kinds of large chips. Please apply high-temperature tape around the component to protect surrounding components.

-

The temperature should be set around 365 °C-400 °C and airflow around 45-65. The nozzle should be kept vertical from the component with a distance of 6-8 mm.

-

You should heat evenly above the component for about 40 seconds. Then pry up the component with a pry blade.

-

In summary, the nozzle of hot air gun should be kept vertical from the soldering surface with a suitable distance. Other than that, the temperature and airflow of the hot air gun must be set properly according to the actual repair circumstances.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

Annuleren: ik heb deze handleiding niet afgemaakt.

8 andere personen hebben deze handleiding voltooid.