Inleiding

The motor powers the rotating head of the toothbrush. If it is damaged or wears out due to use, it will need to be replaced. Some steps in this procedure require desoldering connections. For a review of soldering techniques, check out this How to Solder Guide.

Wat je nodig hebt

-

-

Use the charging station to remove the a small plastic plug from the end of the toothbrush by inserting the charging station into the end insert and twisting counter-clockwise by 90 degrees.

-

-

-

-

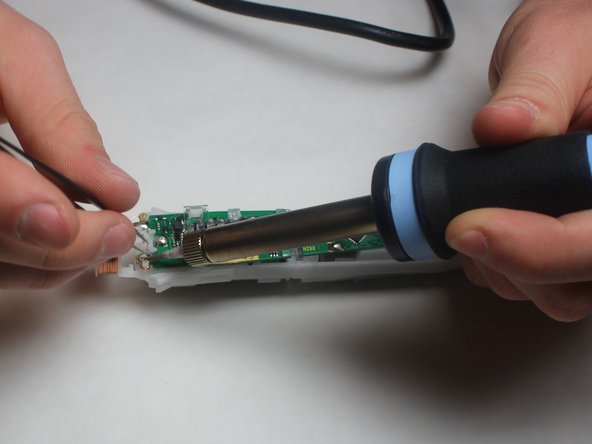

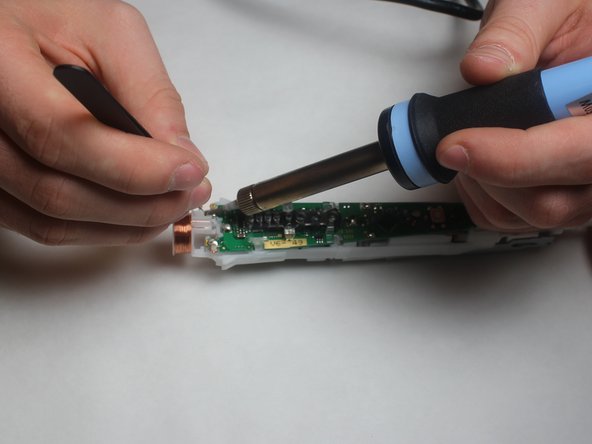

Desolder the red LED wires from the solder pads near the rotating head of the device.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

Annuleren: ik heb deze handleiding niet afgemaakt.

Één andere persoon heeft deze handleiding voltooid.

4 opmerkingen

Hallo,

Super-Anleitung. Kannst Du verraten, was für einen Motor man zur Austausch benötigt?

Spannung, Leistung, Umdrehungen, Maße, etc.?

Und vielleicht eine Bezugsquelle.

Danke Dir,

Kai

Die Spule unten muss nicht ab! Woher bekommst du eine Ersatz motor? Im Internet findet man Nichts?!

Vielleicht bei diesem Verkäufer?

VauWeh -