Inleiding

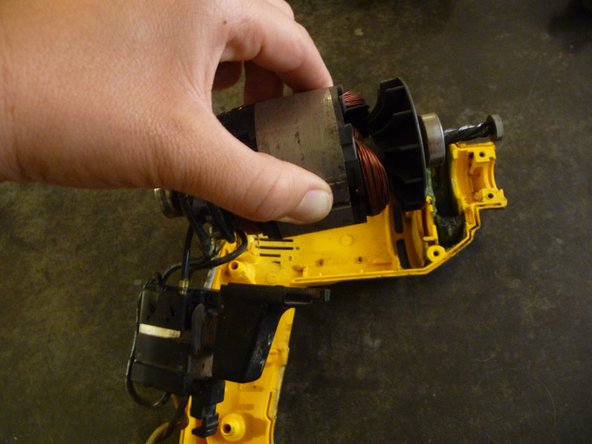

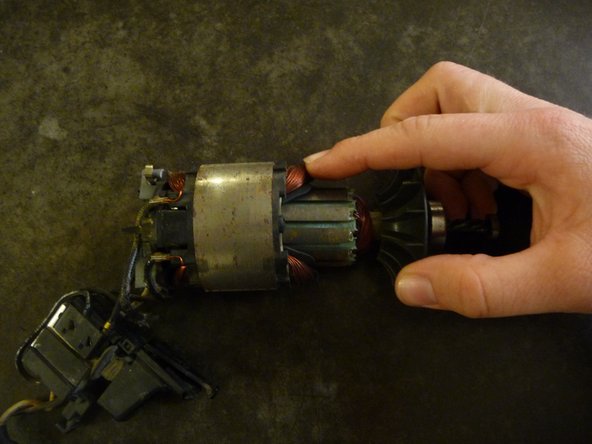

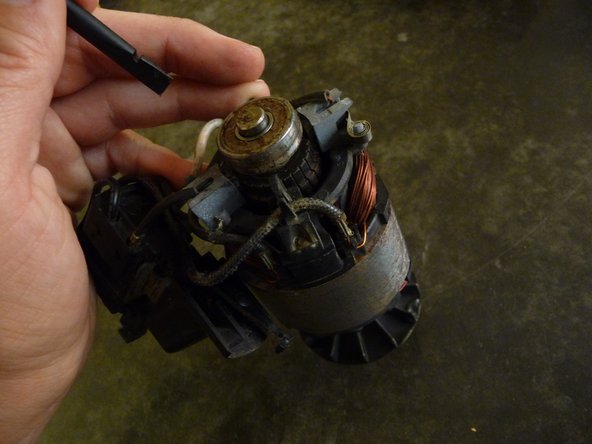

Use this guide to disassemble your drill for cleaning, troubleshooting, or other maintenance.

Wat je nodig hebt

-

-

Remove the seven T20 screws.

-

Use the T-handle configuration of the screwdriver for the necessary force to loosen the screws.

-

-

Plug it in and see if it works more reliably.

Plug it in and see if it works more reliably.

Annuleren: ik heb deze handleiding niet afgemaakt.

4 andere personen hebben deze handleiding voltooid.